As the United States navigates a shifting trade landscape under renewed tariffs, retailers are facing unprecedented challenges.

The retail sector, particularly major players like Walmart, is preparing for the widespread effects of these tariffs, which could impact everything from supply chains and manufacturing to inventory management and pricing strategies.

Given Walmart’s dependence on imported goods and its commitment to maintaining low prices, the retail giant must undertake significant adjustments to mitigate the effects of these policy shifts.

The Tariff Landscape: Shifting Trade Policies and Economic Ramifications

In early 2025, the Trump administration reinstated and expanded a series of tariffs aimed at countering trade imbalances and protecting domestic manufacturing.

These tariffs target a broad spectrum of imports, including raw materials like steel and aluminum, consumer electronics, household goods, and apparel.

With China remaining one of the primary sources of imports for U.S. retailers, the escalation of trade tensions has reignited concerns over increased operational costs, supply chain disruptions, and inflationary pressures on consumer prices.

For retailers, especially Walmart, these tariffs could mean billions of dollars in additional costs, forcing them to either absorb the financial burden or pass it on to consumers.

The company must now adopt a multifaceted approach to safeguard its business model while maintaining consumer trust and affordability.

Diversifying Supplier Networks

Walmart has long relied on China as a primary manufacturing hub for its private-label brands and other essential goods.

With tariffs increasing the cost of Chinese imports, Walmart has accelerated its shift towards alternative sourcing strategies. Countries like Vietnam, India, and Mexico are becoming more attractive as potential supply chain partners due to their lower labor costs and favorable trade agreements.

The retailer is actively working with suppliers in these regions to secure stable production lines, ensuring it can continue offering a broad range of low-cost products.

Investment in Domestic Manufacturing

To reduce dependence on foreign imports, Walmart has pledged to invest $350 billion over the next decade in products that are made, grown, or assembled in the United States.

By fostering domestic production, the company not only mitigates tariff risks but also appeals to consumers increasingly conscious of buying American-made goods.

However, challenges remain in scaling domestic manufacturing to meet Walmart’s volume requirements while keeping costs competitive.

Enhancing Logistics and Distribution Networks

Tariffs increase the urgency for retailers to optimize logistics and distribution channels.

Walmart has ramped up investments in its supply chain technology to improve efficiency and reduce costs. With an extensive network of distribution centers, the company is leveraging AI-driven analytics to optimize freight movement, reduce lead times, and minimize transportation expenses associated with shifting supply chains.

Manufacturing Strategies: Balancing Cost, Efficiency, and Flexibility

The rising cost of labor and tariffs on raw materials have pushed manufacturers toward greater automation.

Walmart is collaborating with suppliers to implement smart factories equipped with robotics, AI, and IoT-based systems. These investments help streamline production, reduce reliance on human labor, and enhance efficiency in response to fluctuating trade policies.

Rather than depending solely on Asian suppliers, Walmart is exploring nearshoring opportunities in Latin America and North America.

Establishing production hubs closer to the U.S. market reduces tariff exposure and lowers transportation costs. Mexico, in particular, presents an advantageous option due to the United States-Mexico-Canada Agreement (USMCA), which offers tariff-free trade on many goods.

Inventory Management: Adapting to a Volatile Trade Environment

Many retailers, including Walmart, have turned to stockpiling goods ahead of tariff hikes to temporarily shield consumers from price increases.

However, this strategy presents risks such as higher warehousing costs and potential inventory surpluses if consumer demand shifts.

Walmart is carefully balancing its stockpiling efforts to avoid overstocking while ensuring product availability.

Shift from Just-in-Time to Just-in-Case Inventory Models

The just-in-time (JIT) inventory model, which minimizes holding costs by syncing inventory levels with real-time demand, is being reconsidered.

\Walmart is now adopting a just-in-case (JIC) approach, maintaining higher inventory buffers for essential goods. This shift ensures better preparedness for supply chain disruptions, though it requires more storage space and capital investment.

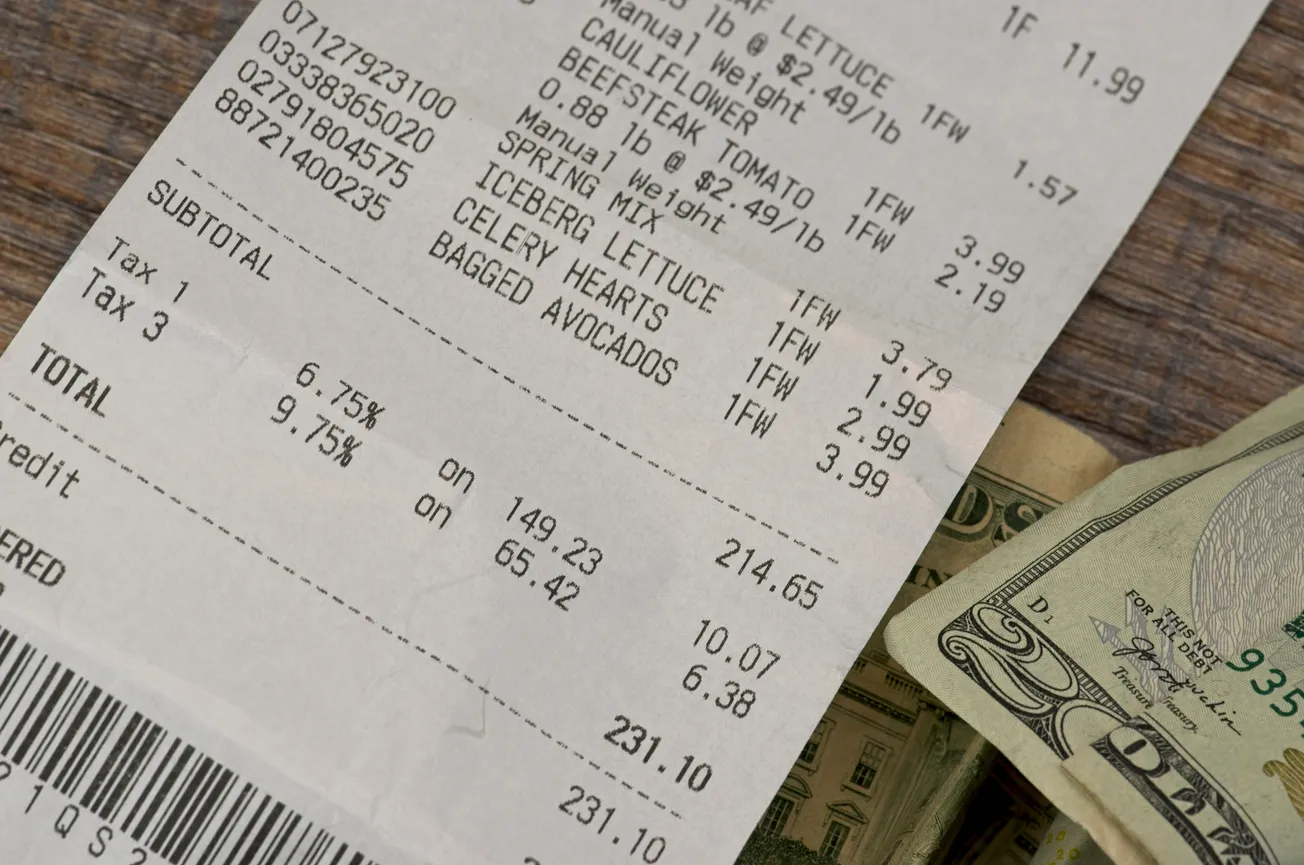

Absorbing Costs vs. Price Increases

Walmart’s core value proposition hinges on affordability.

As tariff-related costs rise, the company must decide whether to absorb the expenses or adjust pricing. In some cases, Walmart may negotiate with suppliers to share the financial burden.

Where cost increases are inevitable, the retailer will employ strategic price hikes, ensuring that increases remain as minimal and selective as possible.

Shrinkflation as a Cost-Saving Measure

Shrinkflation—reducing the size or quantity of a product while maintaining its price—is another tactic being employed by manufacturers.

Walmart is likely to implement this strategy on select private-label goods, allowing it to manage costs without overtly raising prices.

However, as consumers become more aware of shrinkflation tactics, Walmart must carefully balance transparency and value perception.

Predictive Analytics for Demand Forecasting

Walmart is leveraging AI and big data analytics to improve demand forecasting. By analyzing purchasing patterns and market trends, the company can make real-time adjustments to its sourcing and pricing strategies.

AI-driven simulations also help Walmart assess different tariff scenarios and their potential financial impact.

Supply Chain Visibility Platforms

Investments in cloud-based supply chain management platforms allow Walmart to enhance real-time tracking of shipments, supplier performance, and potential disruptions.

Improved visibility enables faster decision-making, reducing the risks associated with tariff-related delays.

Strengthening Supplier Relationships

Open collaboration with suppliers is crucial in navigating tariff-related cost increases.

Walmart is working closely with manufacturers to negotiate better pricing, optimize production efficiency, and share technological advancements. Joint investments in automation and supply chain transparency further enhance resilience against trade disruptions.

Government and Trade Policy Advocacy

As one of the largest U.S. employers and importers, Walmart actively engages with policymakers to influence trade regulations.

The company participates in industry coalitions advocating for balanced tariff policies that protect both domestic manufacturers and retailers.

Tariffs present formidable challenges for Walmart and the broader retail industry, requiring innovative solutions in supply chain management, manufacturing, inventory control, and pricing strategies.

By diversifying sourcing, investing in domestic production, leveraging automation, and employing strategic inventory management, Walmart is positioning itself to navigate these disruptions effectively. While cost pressures will persist, the company’s ability to adapt and maintain its affordability promise will determine its success in the evolving global trade landscape.

As economic and policy conditions continue to shift, Walmart’s proactive approach serves as a case study in retail resilience, setting the stage for the future of supply chain agility in the face of geopolitical uncertainty.